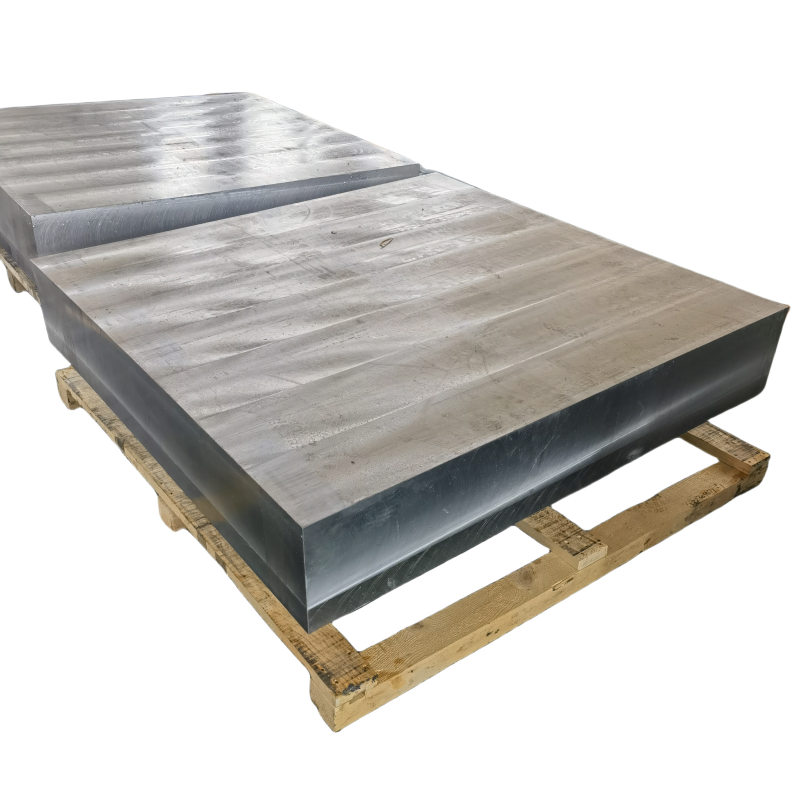

7xxx series aluminum plates are known for their exceptional strength-to-weight ratio, making them a top choice for high-performance industries. In this guide, we’ll break down everything you need to know about this alloy family, from composition, machining and application.

What is 7xxx Series Aluminum?

The 7xxx series aluminum alloy belongs to the zinc-magnesium alloy family (like 7075, 7050, 7475), specially designed for material with high strength. Core features include:

Main ingredients: zinc (5-8%) + magnesium + copper.

Heat Treatment: Most grades with heat treatment (T6/T7 temper) for enhanced durability.

Strength: Tensile strength up to 570 MPa (more than many steel).

Note: Corrosion resistance is slightly lower than 6 series aluminum alloy (coating protection).

7075 is the most common 7xxx series aluminum alloy, the main characteristics are high strength, excellent fatigue resistance, common uses are aviation frame, military equipment, etc

Reason for choosing a 7-series aluminum alloy plate

Ultra-High Strength: Ideal for load-bearing components.

Lightweight: 1/3 the density of steel.

Heat Resistance: Retains properties at elevated temperatures.

Machinability: Achieves tight tolerances with proper tools.

7 series of aluminum alloy plate processing skills

Tool Selection

Cutting Tools: Carbide or polycrystalline diamond (PCD) tools.

Tool Geometry: High rake angles (12°–15°) to reduce heat.

Lubrication: Use mist coolant to minimize friction.

Speed & Feed Recommendations

Milling: 800–1,200 SFM (surface feet per minute).

Drilling: 150–300 RPM with peck drilling to clear chips.

Avoid Chatter: Secure plates with vacuum fixtures.

Post-Machining Care

Stress Relief: Anneal parts to prevent warping.

Anodizing: Apply Type II or III anodizing for corrosion protection.

Common Challenges & Solutions

Stress Corrosion Cracking:

Cause: Residual stresses + humid environments.

Fix: Use T73 temper, apply protective coatings.

Galling During Threading:

Cause: High zinc content.

Fix: Use coated taps; lubricate with heavy-duty oil.

Top Applications of 7xxx Aluminum Plates

Aerospace: Wing spars, landing gear.

Defense: Armored vehicle components.

Sports: Bicycle frames, climbing equipment.

Automotive: High-stress engine parts.

Post time: Mar-14-2025