The main advantages of aluminum alloys compared to conventional steel materials for the production of parts and vehicle assemblies are the following: higher vehicle power obtained by a lower mass of the vehicle, improved rigidity, reduced density (weight), improved properties at high temperatures, controlled thermal expansion coefficient, individual assemblies, improved and customized electrical performance, improved wear resistance and better noise attenuation. Granular aluminum composite materials, which are used in the automotive industry, can reduce the weight of the car and improve a wide range of its performance, and can reduce oil consumption, reduce environmental pollution, and prolong the lifetime and/or exploitation of the vehicle.

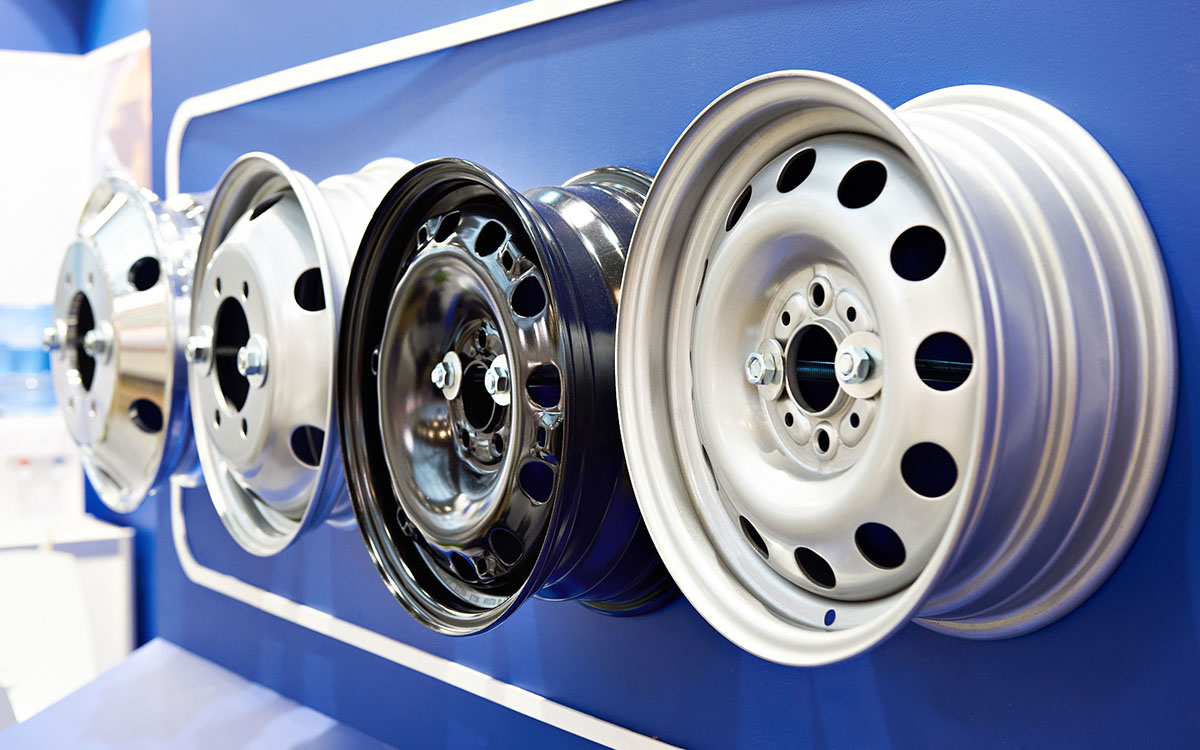

Aluminum is used in the Automobile industry for car frames and bodies, electrical wiring, wheels, lights, paint, transmission, air conditioner condenser and pipes, engine components (pistons, radiator, cylinder head), and magnets (for speedometers, tachometers, and airbags).

Using aluminum rather than steel in the manufacture of automobiles has a number of advantages:

Performance benefits: Depending on the product, Aluminum is typically 10% to 40% lighter than steel. Aluminum vehicles have higher acceleration, braking, and handling. Aluminum’s hardness gives drivers more rapid and effective control. Aluminum’s malleability allows designers to create vehicle designs that are optimized for best performance.

Safety benefits: In case of a crash, aluminum can absorb twice the energy as compared to steel of equal weight. Aluminum may be utilized to increase the size and energy adsorption efficiency of a vehicle’s front and back crumple zones, improving safety without adding weight. Vehicles constructed with lightweight aluminum require shorter stopping distances, which aids in accident prevention.

Environmental benefits: Over 90% of automotive aluminum scrap is recovered and recycled. 1 ton of recycled aluminum can save energy as same as 21 barrels of oil. When compared to steel, utilizing aluminum in automobile manufacturing results in a 20% lower lifecycle CO2 footprint. According to the Aluminum Association’s report The Element of Sustainability, replacing a fleet of steel vehicles with aluminum vehicles may save 108 million barrels of crude oil and prevent 44 million tons of CO2.

Fuel efficiency: Vehicles that have aluminum alloy could be up to 24% lighter than vehicles with steel-component. This results in 0.7 gallons of fuel-saving per 100 miles, or 15% less energy usage than steel vehicles. Similar fuel savings are achieved when aluminum is used in hybrids, diesel, and electric vehicles.

Durability: Vehicles with aluminum components have a longer lifespan and require less corrosion maintenance. Aluminum components are suitable for vehicles operating in extreme environmental conditions, such as off-road and military vehicles.